GALLI: Energy Saving

Today, energy saving is a priority for any company. Galli’s new ovens and dryers reduce consumption by up to 30 percent. Internal supports can be configured by the customer according to their needs. Maximum modularity of work areas designed with the customer.

DURKOPP ADLER: Delta 888 step-motor and much more

Many new features on board the new 888, first and foremost the step-motor that guarantees absolute precision to the movement. All operating parameters can be adjusted from the touch screen panel. The new magnetic sensor detects the thickness of the material and automatically adjusts the stitch length and other parameters such as thread tension. All […]

OMFAS: Customizable manual spray booth

The Velox 1400 stainless steel manual spray booth is ideal for performing leather finishing sampling. It features a new automatic water loading and unloading system that provides significant energy savings. Maintenance reduced to a minimum thanks to its composition in three sectors that can be completely disassembled (Water Veil – Top – Tank). Backlit table […]

GEMATA: Leather finishing with very low environmental impact with GREENFINISH

GREENFINISH is the innovative release paper finishing line that ensures low environmental impact. It starts with GREENSTARs roller coater to coat the chemicals on any kind of leather and continues with infrared drying ovens. The standard line is complete with accumulator and allows non-stop processing 24/24, ideal for tanneries that have large production batches. With […]

ESCOMAR: New through feed sammying machine for wet blue PCR-e8

New pressing system fully controlled by hydraulic power unit capable of developing pressure up to 280 tons. The hydraulic system regulates the drying pressure on 4 independent bridges with 8 pressure points to ensure uniform drying even at low pressures. The machine can work at high speeds of up to 28 mt/min with significant production […]

Cartigliano: The drying crust revolution

NeroRapido Vacuum Dryer dries any type of leather evenly, deeply but gently, at very low temperatures, never above 22-23° C. No fat liquors migration. The result is perfectly dry, round, natural leather without loss of thickness or footing. RadioFrequency drying works only on the water particles contained within the leather. In just a few minutes, […]

GEMATA: very low environmental impact with GREENFINISH

Innovative release paper finishing line with drying tunnel with pyrometers to control the temperature on the paper and on the leather surface. It is the first system to use the GREENSTARs roller coating machine to coat the thermo-adesive on the leathers. Uniform coverage effect on all leathers. Minimisation of environmental impacts with the reduction of […]

STEMA: optimal and certified glue reactivation, thanks to the oven equipped with a thermal imaging camera

Conveyor line with reactivation and drying cells designed specifically for sneakers. In the oven there is a thermal camera that allows to detect, and thus keep under control, the heating of each part of the footwear (toe, upper, heel). The system allows the oven to be programmed with extreme precision ensuring optimal heating of the […]

MM SOLUTION: Complete system for making soles

Energy-saving cutting center with patented mechanical head without the use of compressed air. New numerical milling machine to automatically perform the milling operation of the outer edge of soles. Sophisticated 5-axis interpolated CNC performs various types of inclinations. Working center with two spindles for soles skiving , including rotating axys for soles decoration channeling and […]

WINTECH: trend in sole molding machinery

Energy conservation today is the most current issue being felt by companies. Work is constantly being done to reduce electricity consumption in all facilities. Difficulty in sourcing electronic components and more are driving manufacturers to have to continually reengineer machines to maintain the quality levels characteristic of leading companies but still be able to meet […]

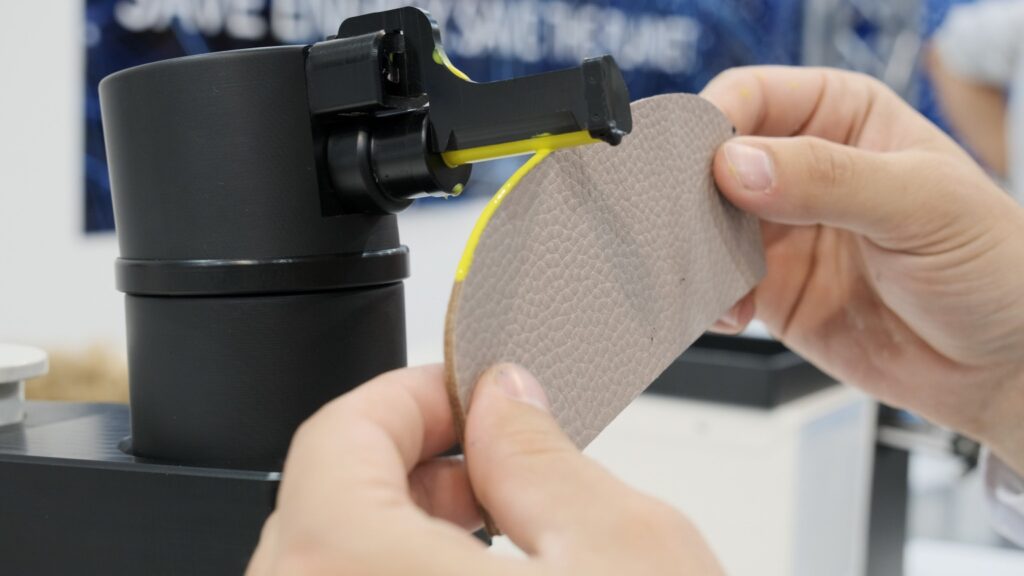

PL PROJECT: Innovative edge dyeing system

Machine that consumes so little electricity that it can be powered by a powerbank recharged at night when energy is cheaper. Wireless magnetic motor. The head can be assembled and disassembled very easily and quickly to do color changes and to clean the components that come in contact with the color. Once closed with the […]

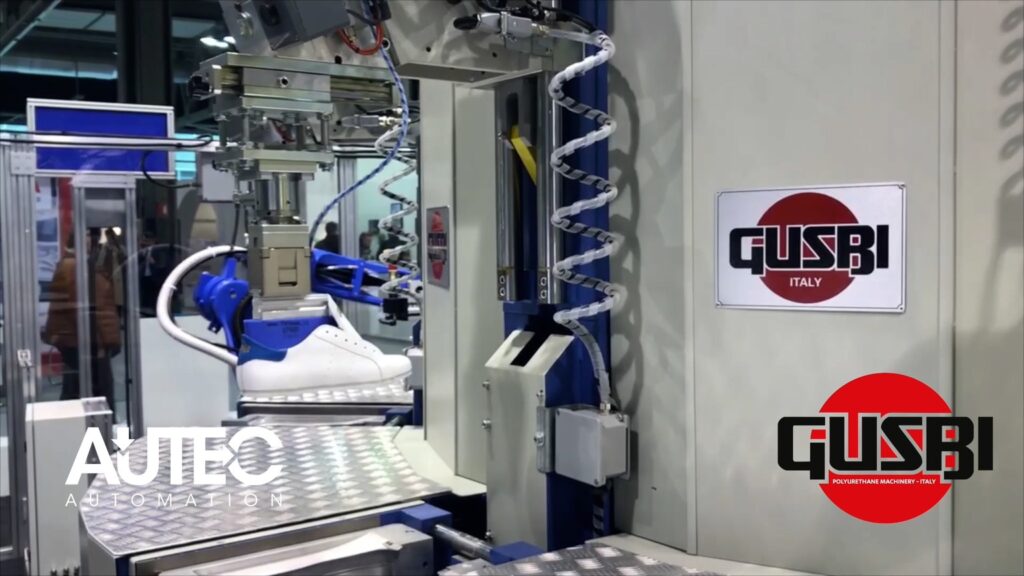

GUSBI: Innovation trends in PU printing

PU machine manufacturers are working in several directions to increasingly improve molding processes for a compound that offers so many advantages over traditional thermoplastics. One trend is the use of polyurethanes with increasingly lower densities to reduce component weight and gain share in applications that require lighter soles. Efforts are being made to achieve maximum […]