I-TECH Innovative Technology: revolutionary Lean Production system

State-of-the-art ad-hoc solutions have been designed for each stage of production to ensure a drastic reduction in raw material consumption and water consumption due to washing operations, as well as a marked reduction in waste and discharge. All this leads to a radical reduction in costs and a significant improvement in the processing system. The […]

NEXUS: Automatic stacking leather (Big Brother)

Automatic system for stacking leather at the exit of another operating machine positioned upstream. It is revolutionary because it performs the same function of traditional stackers in much smaller spaces and without operator intervention, even in case of very shining automotive leathers. Modular system and small sizes. Remote assistance and Industry 4.0.

TODESCO: innovation in spraying (Innover)

Innover spray booth: a system that changes the way leathers are finished under the banner of productivity and reduced maintenance time and color consumption. The booth is all AISI 304 stainless steel, sturdy and finished with care and attention to detail. The innovative arrangement of the fume extraction fan, in direct intake inside the booth, […]

OMFAS: The remotely controlled tailor-made drum

Stainless steel drums of standard dimensions or customizable with 10” PLC touch screen control panel. Supporting structure in tubular stainless steel AISI 304 and components of the highest quality. New interconnection software for remote control from any device. Extremely accurate design with customized logos and graphics.

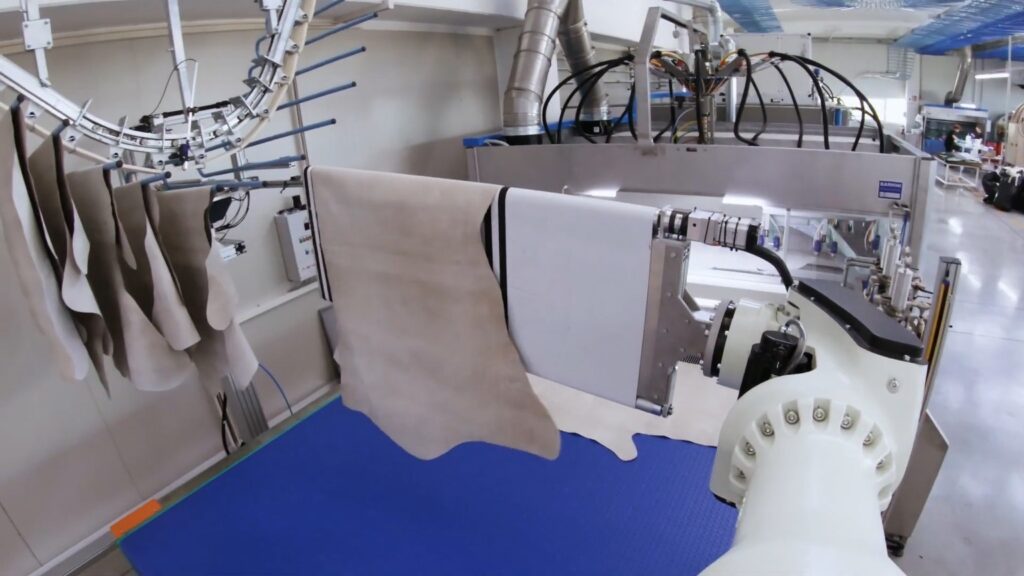

BRS BARNINI: Automated cycle with robots

The robot takes the leather from the overhead chain and places it on the conveyor belt of the finishing line. A brand new automatic system for the entry of hides into tannery machinery replaces heavy and repetitive manual work. The hides, both half and whole, can be loaded by the robot on the processing plant […]

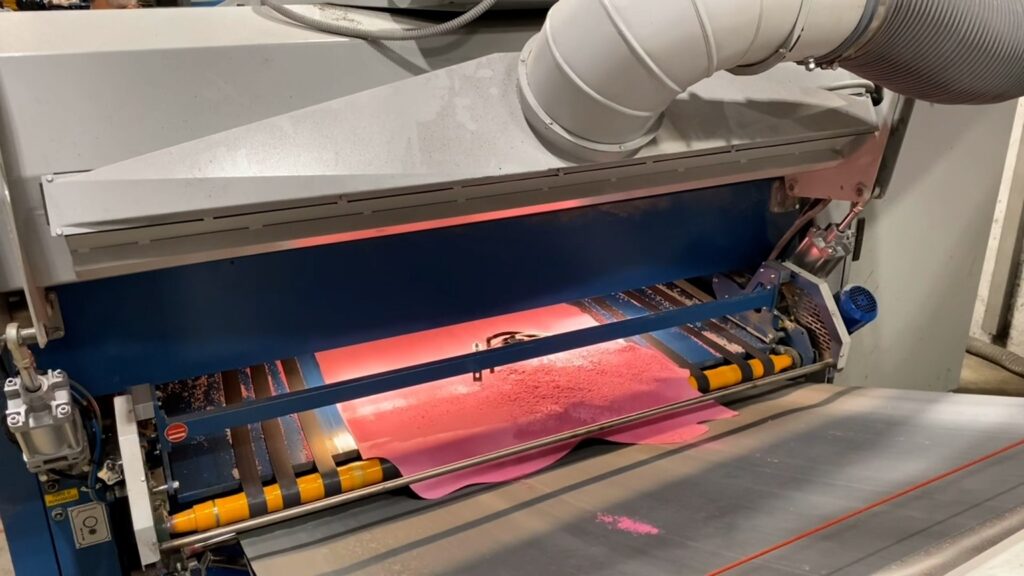

BERGI: continuous belt grinder

The ACTIVE continuous belt grinder was created to process items that require cold processing and increased dust discharge. It is ideal for vegetable-tanned leathers, oiled leathers, automotive putty splits and coil material. The distance between the buffing point and the exit mat is cut in half compared to a conventional buffing machine, resulting in a […]

GEMATA: very low environmental impact with GREENFINISH

Innovative release paper finishing line with drying tunnel with pyrometers to control the temperature on the paper and on the leather surface. It is the first system to use the GREENSTARs roller coating machine to coat the thermo-adesive on the leathers. Uniform coverage effect on all leathers. Minimisation of environmental impacts with the reduction of […]

FALMACH: telemetry Process data monitoring system, air quality and solvent presence

Customized graphics and editing, real-time monitoring and history features make the system easy to use by operators, maintainers or supervisors. The software allows you to have both new and existing machines under control anytime and anywhere, optimizing their use and maintenance. Certified sensor technology also makes it possible to monitor the air quality of workstations.

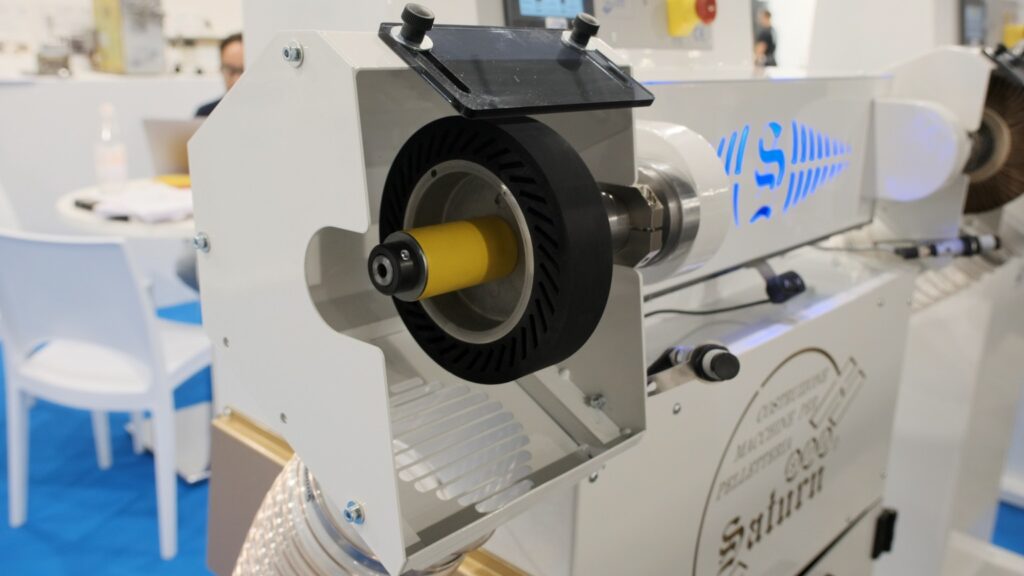

SATURN: Brushing machine with advanced vacuum system

The filtering and collection system is located inside the machine with an obvious reduction in total footprint. Very easy maintenance with no bag to disassemble but with collection basket. HEPA filter provides an advanced level of dust filtering. Proximity sensor allows the machine to be turned off when the operator is not in front of […]

ROBOT SYSTEM AUTOMATION + SEIT ELETTRONICA: Laser bottom roughing on robotized line

The shoe is brought to the robotized cell, the system reads the TAG combined with the RFID present in the last, the information on the model and to choose the work program. The laser is programmed to intervene in different areas of the upper by performing rapid and precise bottom roughing at speeds of up […]

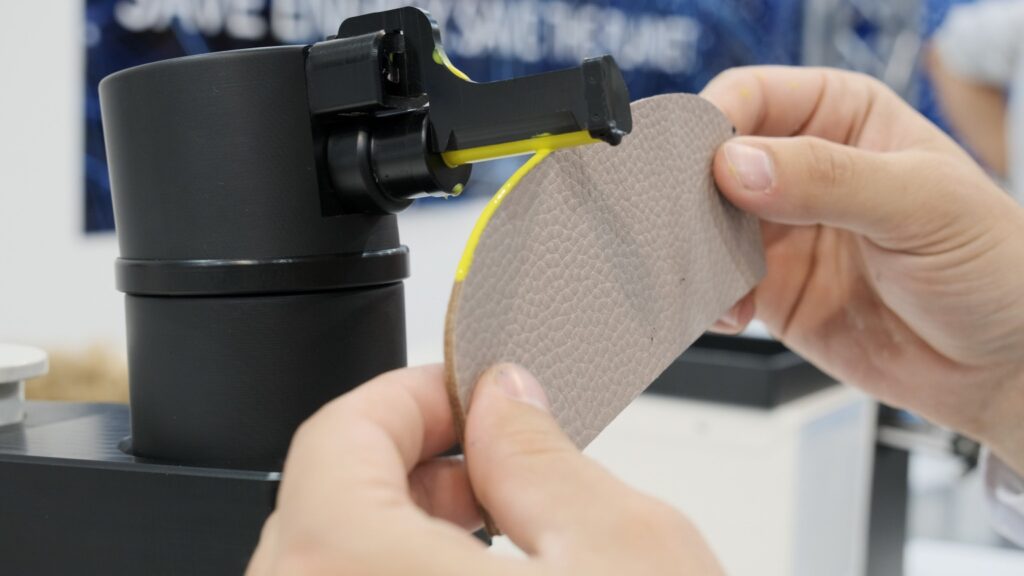

PL PROJECT: Innovative edge dyeing system

Machine that consumes so little electricity that it can be powered by a powerbank recharged at night when energy is cheaper. Wireless magnetic motor. The head can be assembled and disassembled very easily and quickly to do color changes and to clean the components that come in contact with the color. Once closed with the […]

MAIN GROUP: robotic line for sole preparation

Robot to support the automation of gluing the sole. The vision system recognizes the exact position of the sole while the robot following the programmed path, sprays the glue preparing the sole for bonding with the upper. The operation takes place inside a closed chamber equipped with suction to prevent glue dispersion into the environment.